| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Halnn

Model Number : WNGA/DNML/WNMN/SNMN

Certification : ISO9001

Place of Origin : China

MOQ : 10 pcs

Price : Negotiable ( About 10-30 Usd/ Piece)

Payment Terms : T/T, Western Union, MoneyGram,Paypal

Supply Ability : 100000 pcs per month

Delivery Time : 3~15 working days

Packaging Details : 10 pcs in one plastic box inside, carbon box outside

Insert Garde : WNGA

Dimension : Customer-made

Body : Tungsten Carbide

Origin Country : Henan,China

Mnchining Material : Finish Machining

Brade : Halnn Tools

Color : Black

Application : Grey Cast Iron

Rough cutting Gray Cast Iron Brake Drum / Disc with Halnn Tools CBN Tip

1. Halnn Tools CBN Tips High speed Machining Grey Cast Iron Brake Drum

In previous times, people adopt common lathe and carbide insert to machine brake

disc, the process is roughing-semi-finishing-finishing. With the improved requirement on the surface quality and the production qty, they change the common lathe to CNC Lathe, but the carbide insert can’t machine with high cutting speed, they also can’t improve the efficiency, so they will choose other insert materials to satisfy the CNC lathe. CBN Insert became their right choice.

2. Why we Choose Halnn Tools CBN Tips High speed Machining Grey Cast Iron Brake Drum

Gray cast iron has low hardness and can be processed by traditional carbide tools. But why choose a CBN inserts that is more expensive than traditional carbide tools?

Gray cast iron material is mainly used in machine tools, automobiles and other industries. Most of the parts are mass-produced, which requires high production efficiency. Although traditional carbide tools can also process gray cast iron, the processing efficiency is low and only suitable for small batch production. , or occasionally processing gray cast iron parts.

3.CBN Tip Characteristics

| Insert Grade | Binder | CBN Content(%) | Granularity | Hardness(HV) | Cutting Depth | Condition |

| BN-K10 | Si,Co | 95 | ≤ 2 | 3300—3500 | ≤1.5mm | Continuous |

| BN-K20 | AL | 95 | 2—4 | 3400—3600 | ≤0.5mm | Continuous |

| BNK30 | Si,TIC | 97 | 2—4 | 3400—3600 | ≤0.5mm | Continuous |

4.Pictures of Halnn Tools CBN Tip

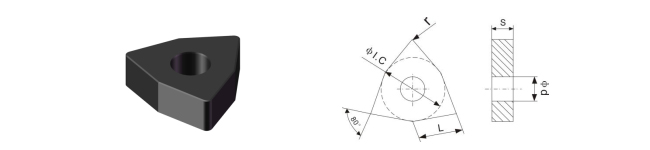

5.Detailed Data of WNGA CBN Tip

| ||||||||||

| Type | Dimension | Standard Chamfer | Grades | |||||||

| L(mm) | φI.C(mm) | φd(mm) | S(mm) | r(mm) | BNK30 | BN-S300 | BN-S20 | BN-S200 | ||

| WNGA080404 | 8.7 | 12.7 | 5.16 | 4.76 | 0.4 | S01015 S01020 S02020 S02025 | ● | ● | ● | ● |

| WNGA080408 | 8.7 | 12.7 | 5.16 | 4.76 | 0.8 | ● | ● | ● | ● | |

| WNGA080412 | 8.7 | 12.7 | 5.16 | 4.76 | 1.2 | ● | ● | ● | ● | |

6.Application Case

As shown in the figure, the processing effect of Halnn solid CBN inserts---BN-S300 CBN grade finishing gray cast iron brake disc end face.

Machining workpiece: brake disc

Processing: Finishing

Processing part: end face (brake surface)

Tool number: BN-S300 SCGN090408

Machining method: double CBN inserts processing end face at the same time

Cutting parameters: Cutting depth (ap)=0.25mm,

Feed rate(Fr)=0.2mm/r,

Cutting speed(Vc)=800m/min

Processing method: dry cutting

Processing effect: compared with coated carbide inserts, the results are as follows

| Tool material | Inserts type | Line speed | Single edge life |

| Halnn BN-S300 CBN grade inserts | SCGN090408 | 800m/min | 300pcs/edge |

| coated carbide inserts | CNMG120408 | 300m/min | 15pcs/edge |

7. Our service

|

|

Rough cutting Gray Cast Iron Brake Drum / Disc with Halnn Tools CBN Tip Images |