| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Halnn

Model Number : DNML/DNMN/SCGN/SNMN

Certification : ISO9001

Place of Origin : China

MOQ : 10 pcs

Price : Negotiable ( About 10-30 Usd/ Piece)

Payment Terms : T/T, Western Union, MoneyGram,Paypal

Supply Ability : 100000 pcs per month

Delivery Time : 3~15 working days

Packaging Details : 10 pcs in one plastic box inside, carbon box outside

Weight : 16G

Dimension : Customer-made

Body : Tungsten Carbide

Origin Country : Henan,China

Mnchining Material : White cast iron

Brade : Halnn Tools

Insert Garde : DNML

Application : Cast Iron

Roughing Cast Iron Brake Disc with Halnn Tools DNML110604 CBN Cutting Tool

1. Halnn Tools CBN Cutting Tool Cutting Cast Iron Brake Disc

As the main components of the large automobile industry, the brake drum determines its driving safety, so the quality of the brake drum is particularly important. As the friction coupler of the drum brake, the brake drum should have the highest and stable friction coefficient as well as the appropriate wear resistance, heat resistance and heat dissipation in addition to the strength and rigidity required as the member. As the main application materials, gray cast iron is often used as the heat capacity.

2. Why we Choose Halnn Tools CBN Cutting Tool Cutting Cast Iron Brake Disc

Gray cast iron, because of its good shock absorption, is often used in many industries, such as the automotive industry, machine tool industry. And the hardness is not high, generally around HB200, using traditional carbide tools can be completed.

However, many factories that process gray iron castings are now profitably low. The main reason is that the price of raw materials is rising, but the company itself is still the same product. The same process, without any change, will only result in lower profits.

Many large companies have switched to ultra-hard tooling, resulting in improved efficiency and improved costs. The price of a superhard tool is several times that of a carbide tool, but the number of workpieces is several times that of a carbide tool, and the efficiency is significantly improved.

3.CBN Cutting Tool Characteristics

| Insert Grade | Binder | CBN Content(%) | Granularity | Hardness(HV) | Cutting Depth | Condition |

| BN-S300 | AL,TIC | 97 | 4—6 | 3400—3600 | ≤2mm | Continuous |

| BN-K10 | Si,Co | 95 | ≤ 2 | 3300—3500 | ≤1.5mm | Continuous |

| BN-K20 | AL | 95 | 2—4 | 3400—3600 | ≤0.5mm | Continuous |

| BNK30 | Si,TIC | 97 | 2—4 | 3400—3600 | ≤0.5mm | Continuous |

4.Pictures of Halnn Tools CBN Cutting Tool

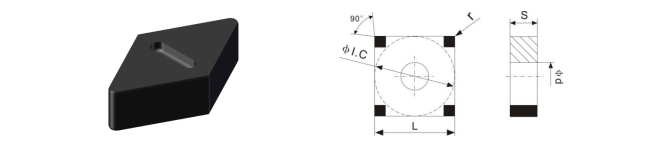

5.Detailed Data of DNML CBN Cutting Tool

| |||||||||

Type | Dimension | Standard Chamfer | Grades | ||||||

| L(mm) | φI.C(mm) | S(mm) | r(mm) | BN-K1 | BN-S20 | BN-S200 | BN-S300 | ||

| DNML110604 | 11.6 | 9.525 | 6.35 | 0.4 | S01020 S02020 | ● | ● | ● | ● |

| DNML110608 | 11.6 | 9.525 | 6.35 | 0.8 | ● | ● | ● | ● | |

| DNML110612 | 11.6 | 9.525 | 6.35 | 1.2 | ● | ● | ● | ● | |

6.Application Case

BN-S300 grade belongs to the solid CBN insert, which has excellent wear resistance, heat resistance and fracture resistance, making it widely used in the field of rough brake drums.

Take the BN-S300 grade rough brake drum as an example:

Workpiece material: gray cast iron

Workpiece hardness: HB180-241

Surface finish: Ra3.2

Inserts Grade: BN-S300 CNMN120716

Cutting parameters: Cutting Speed (Vc)=280m/min, Feed Rate(Fr)=0.9mm/r, Cutting Depth(ap)=2.5mm.

7.Product Certificate

|

|

Roughing Cast Iron Brake Disc with Halnn Tools DNML110604 CBN Cutting Tool Images |